- #Cnc screen display function generator

- #Cnc screen display function manual

- #Cnc screen display function software

- #Cnc screen display function series

Cnc Screen Display Function Software And Hardware Most i-Series controls that do not include FOCAS can have it added as an option by FANUC for around 1000machine. This port is most likely located behind the operator screen, or in the main electrical cabinet. Machines equipped with FOCAS just need an Ethernet cable run through the machines body and into the embedded ethernet port. In fact, connecting to machines via FOCAS is so simple, it can often be accomplished without the aid of MachineMetrics on-site technicians. MachineMetrics uses these libraries to access information directly from the control via ethernet. When a machine is equipped with a modern, FOCAS-enabled FANUC control, it is MachineMetrics preferred method for data collection.

#Cnc screen display function series

(1) Single segment execution key: STEP, SBK, SINGLE BLOCK, BLK. The automatic machining key is used for the mode selection during machining.

#Cnc screen display function manual

In automatic or manual processing, the spindle speed, feed rate, and idle travel speed can be adjusted, such as SPINDLE SPEED SWITCH, FEEDRATE OVERRIDE SWITCH.

#Cnc screen display function generator

(6) Manual pulse generator (can realize micro-feed): JOCHANDWHEEL. (5) Manual data input: MDI, MANUAL DATA INPUT, MDA.

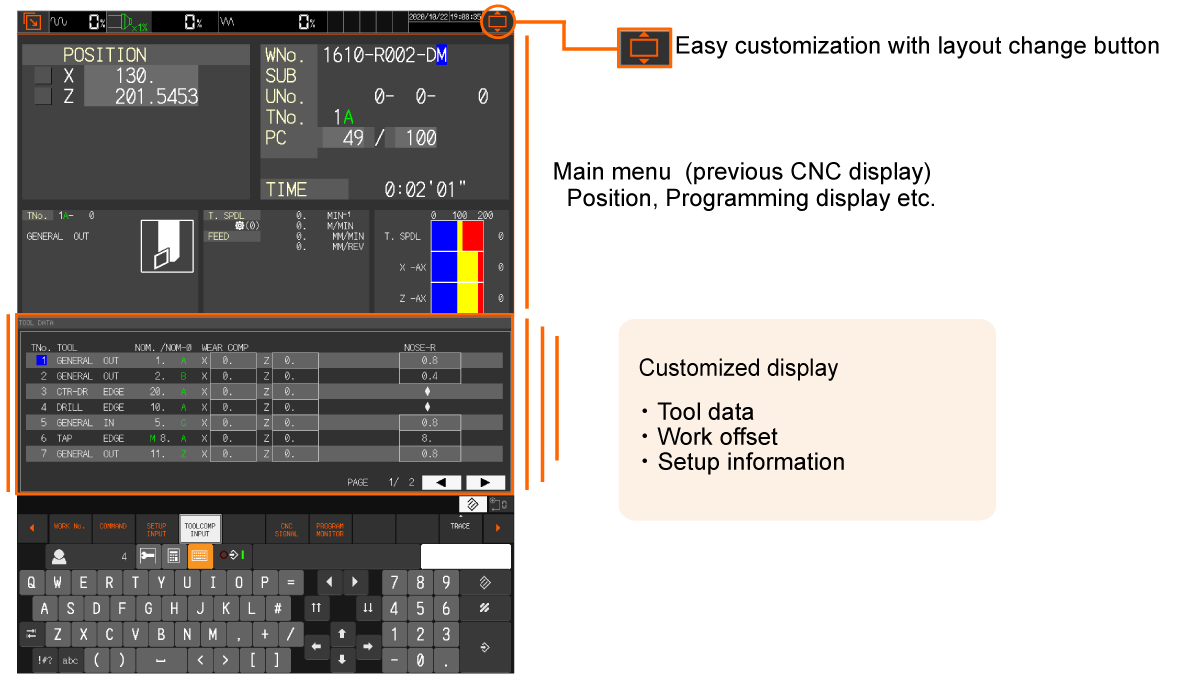

(2) Feed amount setting key: Incremental feed JOG INCREMENTAL. (1) Spindle function setting keys: SPINDLECW (FWD), CCw (REV), OFF, SPINDLELEFT, STOP, RICHT. Manual keys are used for manual operation of CNC machine tools. (1) Block end key, also known as block input key, confirmation key, and enter key It consists of numbers and symbols, such as 1, 2, 3, +, / etc.Įdit keys are used to input and modify programs. I, J, K – the center coordinates of the arc X(u), Y(V), z(w) – absolute (incremental) coordinates: S-spindle speed (r/min) or linear speed (m/min): G, M-preparation function, auxiliary function command: Also known as letter keys, used to input English letters. There may be several sub-functions under a main function. The functions of the soft keys vary with the status of the main function, and their meanings are displayed at the bottom or right of the current screen at the corresponding soft key position. Common main functions are manual (MAN, MANUAL OPERATION, JOG), automatic (AUTO, AUTO-MATIC OPERATION), zero return (REFERENCE POINT, ZERO, HOME), editing (EDIT, PROCRAM EDIT), graphic simulation (GPS, CRAPH, CRAPH.ICS), parameter setting (PARAM, PARAMETER, MENUOFFSET), storage communication (EXT, EXTEINAL, IN/OUTPUT, LOAD/SAVE), self-check (CHECK, DGNOS, DIAGNOSTICS), etc. After power on, first select the main function key, enter the main function state, and then select the lower sub-function to perform specific operations. The main function keys are also called mode keys and status keys. The CNC machine keyboard contains the following control keys (buttons, knobs). The CNC machine control panel consists of a display screen and a keyboard.

0 kommentar(er)

0 kommentar(er)